I really enjoyed meeting everyone at the at the Philadelphia 3D printer workshop Meetup last night.

Here is a copy of the presentation I gave:

3D Printer Software Toolchain

To answer some questions I was asked

The 3D Printer that I use is a Mendel90 that I built from akKit

It was designed and sold by Chris Palmer, AKA NopHead

Here are instructions on how to order it: Mendel90

The Slicer software I'm currently using is Slic3r v0.9.10b

http://slic3r.org/download

Originally the printer came with Skienforge

The Printer Controller software I'm currently using is Repetier Host

http://www.repetier.com/

Originally the printer came with Pronterface

Mendel90 3D Printer

Wednesday, October 23, 2013

Monday, April 22, 2013

Assembly - Part 2

04/22/2013

Continued working on assembly after work today.

It's really starting to look like a 3D printer.

By the way, all these photos are taken with my Samsung Galaxy S3 Cell phone camera

|

| Frame |

|

| Y Carriage parts |

|

| Y Carriage with Hotbed |

|

| The backside showing ribbon cable on Y Carriage |

|

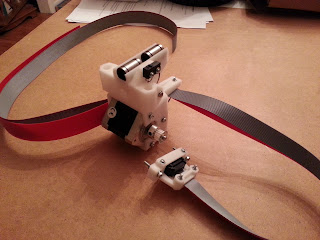

| X Carriage Head base |

|

| Nozzle |

|

| Hot End Circuit board - back (Pretty good soldering eh) |

|

| Hot End Circuit board - Front |

|

| Extruder motor asssembly |

|

| Extruder Motor assembly |

Sunday, April 21, 2013

Assembly

04/20/2013

I am very impressed with the kit that Nop Head prepared.

Clear instructions, Very well packaged and everything's clearly labeled

04/21/2013

X Motor Assembly

In the instructions, each sub-assembly is in a separate section. it starts out with a parts list of required Vitamins, Goodies and Printed parts. I start each sub-assembly by counting out the parts needed for that section, and putting the small parts in a Chinese carryout tray.

Z Motor Assembly

Z Axis Assembly

Nop Head has designed a really nice wire handling system by using ribbon cables for the flexible bridged

I am very impressed with the kit that Nop Head prepared.

Clear instructions, Very well packaged and everything's clearly labeled

|

| Small Parts Lables |

|

| X Idler Assembly |

X Motor Assembly

In the instructions, each sub-assembly is in a separate section. it starts out with a parts list of required Vitamins, Goodies and Printed parts. I start each sub-assembly by counting out the parts needed for that section, and putting the small parts in a Chinese carryout tray.

|

| Parts layed out for X Motor Assembly |

|

| X Motor Assembly |

|

| X Motor Assembly |

|

| Parts for Z Motor assembly |

|

| Closeup - Z Motor Assembly Parts |

|

| Closeup - Z Motor Assembly Parts |

Z Axis Assembly

|

| Parts for Z Axis assembly includes previous sub-assemblies |

|

| Left Side Z Axis Assembly |

|

| Right Side Z Axis Assembly |

|

| Y Idler Assembly |

|

| Y Motor Assembly |

|

| Soldered up the ribbon cable to the Hot Bed and thermister |

|

| Completed Y Carriage Assembly |

|

| Completed Y Carriage Assembly |

Painting

04/20/2013

So last night I went to several places trying to find the Honeydew Krylon Fusion spray paint, but I could not find that color. I ended up going with my second choice which was Patriotic Blue #2329.

The color scheme was inspired by this particular photo which I had seen recently on the Airshow and Aviation Photography Google+ Community.

|

| Photo by Andre Lamerant |

|

| Painted DiBond Panels |

|

| Closeup |

|

| Materials |

The Kit Arrives

Wednesday, April 17, 2013

Mendel90 Kit Build

I'm starting this blog to document the process for getting a 3D printer running at home.

Earlier this year, I joined the 3D Printing community on Google+

It's a very dedicated and talented group, and has been both very informative and inspirational.

I came down to a short list which included the following printers:

Bukobot 8 Vanilla kit by Deezmaker

Rostock Max kit by SeeMeCNC

Mendel90 kit by nop head

After reading lots of reviews and asking some questions I settled on the Mendel90 design.

I really like how nop head has simplified the design, and it looks to be very rigid, and gets very positive reviews from it's users. Both for functionality and quality of prints. The frame is made from panels of DiBond, which is constructed of aluminum skins with a polyetheylene core. The cost was also very reasonable. I have lots of ideas for future improvements, but this one should get me going quickly with high quality prints. I also like that nop head is fully dedicated to the open source concept.

Mendel90 Specifications:

RepRap Wiki Page

nop heads blog post

Github page with Parts lists

04/07/2013

I ordered a Mendel90 kit from nop head in England.

The best way to order is via email using his Gmail address, which is what I did.

He has recently begun to sell parts kits.

He does not supply the power supply unit to the USA or Canada.

Even though the demand is very high, He was backordered of only about 2 weeks.

04/09/2013

I purchased a like new 650 Watt Ultra LSP650 Power Supply Unit on eBay.

The users manual available here: http://static.highspeedbackbone.net/pdf/ULT-LSP650_Manual.pdf

$28.85 with $10.00 for shipping

ULTRA LSP650 output

+3.3V 24A

+5.0V 32A

+12V 38A

04/11/2013

I purchased 2 lbs of 3mm Taulman 618 nylon filament directly from www.taulman3d.com

2 x $19.75 + $11.50 for shipping and handling.

The properties of this filament sounded very interesting to me when I first heard of it, and now all I hear are positive reviews. I'll probably try some PLA, and ABS also.

I also ordered on eBay, a few small Peltier solid state thermal panels and some 20A terminal strips to play with.

04/15/2013

I received an Email that my printer was nearly ready to ship, and that it was time to send payment. The cost was £484.00 + £60.00 S&H = £544.00 GBP = $834.44 USD.

I submitted payment via Paypal for $834.44 USD to The Nopbotshop.

04/16/2013

I received the 2 x 1lb spools of 3mm Taulman 618 Nylon.

I studied up on the painting the DiBond panels which make up the Mendel90 Structure.

Apparently the DiBond factory finish is a polyurethane paint.

The DiBond fabrication guide is here:

http://www.advancedpanelproducts.com/download.html?u=dl49e3b944e7db9&t=d

Many people have had success with this painting process for DiBond panels:

My daughter chose this paint color for the DiBond panels:

Honeydew # 2335

04/14/2013

I modified the wiring on the Power Supply Unit.

04/17/2013

I received an email notification that my Mendel90 is shipping Via UPS.

I also received a tracking number. According to UPS, the kit should be delivered by the end of the day, Friday 04/19/2013. Wow that's fast if it really comes that quickly!

PSU Wiring

I added a 10 Ohm, 10 Watt resistor, a switch and some LEDs to the wires, so that I could test the PSU... Seems to be working OK, I tested all the outputs with a voltmeter (12.20V, 5.15V & 3.31V), and looked at the 12V on a scope... about +/-50mv Ripple... not too bad, but I would have liked better. It may improve under load.

Earlier this year, I joined the 3D Printing community on Google+

It's a very dedicated and talented group, and has been both very informative and inspirational.

I came down to a short list which included the following printers:

Bukobot 8 Vanilla kit by Deezmaker

Rostock Max kit by SeeMeCNC

Mendel90 kit by nop head

After reading lots of reviews and asking some questions I settled on the Mendel90 design.

I really like how nop head has simplified the design, and it looks to be very rigid, and gets very positive reviews from it's users. Both for functionality and quality of prints. The frame is made from panels of DiBond, which is constructed of aluminum skins with a polyetheylene core. The cost was also very reasonable. I have lots of ideas for future improvements, but this one should get me going quickly with high quality prints. I also like that nop head is fully dedicated to the open source concept.

Mendel90 Specifications:

- Build volume 200mm x 200mm x 200mm

- Filament 3mm

- Nozzle size 0.4mm

- Footprint 465mm x 419mm

- Height 400mm, with spool 609mm.

RepRap Wiki Page

nop heads blog post

Github page with Parts lists

04/07/2013

I ordered a Mendel90 kit from nop head in England.

The best way to order is via email using his Gmail address, which is what I did.

He has recently begun to sell parts kits.

He does not supply the power supply unit to the USA or Canada.

Even though the demand is very high, He was backordered of only about 2 weeks.

04/09/2013

I purchased a like new 650 Watt Ultra LSP650 Power Supply Unit on eBay.

The users manual available here: http://static.highspeedbackbone.net/pdf/ULT-LSP650_Manual.pdf

$28.85 with $10.00 for shipping

ULTRA LSP650 output

+3.3V 24A

+5.0V 32A

+12V 38A

04/11/2013

I purchased 2 lbs of 3mm Taulman 618 nylon filament directly from www.taulman3d.com

2 x $19.75 + $11.50 for shipping and handling.

The properties of this filament sounded very interesting to me when I first heard of it, and now all I hear are positive reviews. I'll probably try some PLA, and ABS also.

I also ordered on eBay, a few small Peltier solid state thermal panels and some 20A terminal strips to play with.

04/15/2013

I received an Email that my printer was nearly ready to ship, and that it was time to send payment. The cost was £484.00 + £60.00 S&H = £544.00 GBP = $834.44 USD.

I submitted payment via Paypal for $834.44 USD to The Nopbotshop.

04/16/2013

I received the 2 x 1lb spools of 3mm Taulman 618 Nylon.

|

| 2 x 1lb spools of Taulman 618 Nylon Filament |

I studied up on the painting the DiBond panels which make up the Mendel90 Structure.

Apparently the DiBond factory finish is a polyurethane paint.

The DiBond fabrication guide is here:

http://www.advancedpanelproducts.com/download.html?u=dl49e3b944e7db9&t=d

Many people have had success with this painting process for DiBond panels:

- Scuff surface with red Scotchbrite.

- Wipe surface with Acetone,

- Spray paint with Krylon Fusion for Plastic

- Let dry completely between coats or it may orange peel

My daughter chose this paint color for the DiBond panels:

Honeydew # 2335

04/14/2013

I modified the wiring on the Power Supply Unit.

|

| The cable ends cut off |

|

| Inside the Ultra LSP650 |

|

| Wires rebundled together for Mendel90 |

|

| PSU Back together again |

04/17/2013

I received an email notification that my Mendel90 is shipping Via UPS.

I also received a tracking number. According to UPS, the kit should be delivered by the end of the day, Friday 04/19/2013. Wow that's fast if it really comes that quickly!

PSU Wiring

I added a 10 Ohm, 10 Watt resistor, a switch and some LEDs to the wires, so that I could test the PSU... Seems to be working OK, I tested all the outputs with a voltmeter (12.20V, 5.15V & 3.31V), and looked at the 12V on a scope... about +/-50mv Ripple... not too bad, but I would have liked better. It may improve under load.

|

| Wire Connections |

Grey: (Power OK) to Blue LED (lights when 12V,5V,3.3V output is on and within spec.)

Purple: (5VSB) to Red LED (lights when PSU is plugged in and on

Orange: (3.3V Sense) Connected to larger guage3.3V orange wire

Blue Wire: (-12V) NC - Tucked back into sheathing

Green: (Power ON) to on/off switch

Red: (+5V) 10 Ohm, 10 Watt load resistor

The Mendel90 Controller will only use the bundle of yellow and black wires for 12V power, The rest I'll hook up to a terminal strip to allow for potential future upgrades.

Red: (+5V) - maybe some RGB LEDs?

Yellow: (+12V) I split out 4 yellows for use as auxilliary 12V

Orange: (+3.3V) - maybe for my Teensy 3.0?

Black: (COM) Ground wires

For now I'll just leave them as pigtails, and once I get the printer up and running, I can create a switch/indicator panel, and a terminal block holder.

So now I must just be patient...just be patient...be patient...

04/18/2013

Gack! UPS package tracking page just says "adverse weather condtions"...What does that mean!?!?

Well at least the scheduled delivery time hasn't changed...Yet

04/19/2013

09:00 Woohoo!! Out for delivery!

Hmmm... Suddenly I'm not feeling so well maybe I should leave work early today :-)

Subscribe to:

Posts (Atom)